A 3D Model is a digital representation of an object in three dimensions is a digital representation of an object in three dimensions — width, height, and depth. Unlike a flat image or drawing, a 3D model can be viewed and rotated from any angle, making it ideal for creating physical objects with a 3D printer.

Most 3D models are made up of a mesh A collection of vertices, edges, and faces (typically triangles or quadrilaterals) that define the shape of a 3D object. , which is a collection of tiny triangles (called polygons) connected together to form the surface of the object. The smoother the surface, the more triangles are used.

These files usually come in formats like .STL (the most common format for 3D printing, stores only the shape of the object), .OBJ (Similar to STL, but also supports color, textures, and material data), or .3MF (modern format designed for 3D printing, storing more detailed information like color, materials, and print settings).

Before you start printing, you need something to print!

Where Do 3D Models Come From?

- Download pre-made models from online libraries;

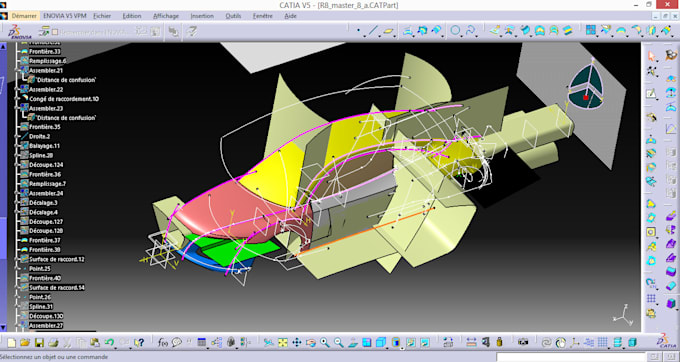

- Design your own using 3D modeling software like Tinkercad, Fusion 360 or SketchUp (see Advanced chapter)

- Scan real-world objects using 3D scanners or smartphone apps.

Understanding how 3D models work helps you choose the right file, fix problems before printing, and even start creating your own designs.

If you’re not quite ready to design your own 3D models,don’t worry — there’s a huge community of makers who share their designs online. Many of these models are available for free and ready to download.

Popular 3D Model Repositories:

- Thingiverse – large, community-driven platform filled with free models for all kinds of projects. Great for beginners;

- Printables.com – offers a curated selection of high-quality models, often with detailed instructions and user reviews;

- Cults3D – features both free and paid designs, with a focus on artistic and creative prints.;

- Thangs.com – includes commercial-use options.

Some models are free to download and print, but not all allow selling or remixing. Make sure to respect the creator’s terms.

Bonus Tips

- Use search filters to narrow down categories, such as "functional parts," "toys," or "household items."

- Read user comments and reviews to avoid failed prints or missing parts.

- Support creators by leaving feedback or donating if you love their work.

In the next chapters, we’ll cover how to prepare a model for printing — so once you’ve found something cool, you’ll be ready to make it real.

Once you’ve found and downloaded a 3D model

(

.STL or .3MF

Common file formats for 3D models. .STL (Stereolithography) and .3MF (3D Manufacturing Format) store geometry data for use in 3D printing.

),

you’re ready to start the journey from digital file to physical object. But before you can hit “print,” there are a few important steps to follow.

You’ll need a slicer All the information related to a 3D printer, such as material specifications, layer height, and extruder type, is first inputted into the slicer. —a program that prepares your model for the printer by converting it into layers and generating G-code, the instructions your printer follows.

Popular slicer programs:

- Ultimaker Cura – beginner-friendly and supports many printers

- PrusaSlicer – great for Prusa printers and many others

- Bambu Studio – optimized for Bambu Lab printers

In the slicer, you can:

- Scale, rotate, or duplicate your model

- Set print parameters like layer height, infill, and supports

More details on these settings are covered in the “3D Printer” chapter.

Some models may have issues like holes or bad geometry that can cause failed prints.

Helpful repair tools:

- Microsoft 3D Builder – simple and built into Windows

- Netfabb – online repair by Autodesk

- Meshmixer – good for mesh editing and repair

- Many slicers include auto-repair features Automatically correct errors like holes, intersecting faces, and non-manifold geometry, ensuring a more reliable printing process.

Once sliced, export your G-code and transfer it to the printer using:

- SD card or USB stick

- Wi-Fi, if your printer supports it

- USB cable, in some setups

Then hit "print" and watch your model come to life!

Extra Tip: Check user comments and photos where you downloaded the model. Community feedback can help you avoid issues before printing.

In the next chapter, we’ll look deeper into slicer settings and how they affect your final print.

Test the knowledge you have accumulated from this chapter by completing this interactive Quiz Test!

Introduction

3D modelling is the process of creating a digital representation of a physical object using specialized software. In this chapter, we’re going to look at how 3D models are built, what terminology you’ll encounter, and how geometry and modeling tools work together to produce printable results. You’ll also get introduced to two commonly used free modeling platforms: TinkerCAD and SketchUp.

Common Terms and Definitions

Before we get into practical use, here are essential terms you'll come across:

- Vertex – a single point in 3D space. Multiple vertices connect to form edges.

- Edge – a straight line between two vertices.

- Face – a flat surface bounded by edges. Most 3D models are made up of triangular or quadrilateral faces.

- Mesh – a collection of vertices, edges, and faces that defines the shape of a 3D object.

- Extrude – a function that turns a 2D shape (like a circle) into a 3D object (like a cylinder) by giving it depth.

- Boolean Operations – functions that combine objects (union), subtract one from another (difference), or find the shared space (intersection).

- Manifold (Watertight) – a 3D model that is completely enclosed, with no holes or non-connected edges. This is required for 3D printing.

- Normals – directions assigned to faces. All normals should point outward for printable objects.

- Parametric Modeling – a method of designing where dimensions and constraints can be changed later, updating the model automatically.

Free 3D Modeling Software: Advantages & Disadvantages

There are several excellent free tools available for creating 3D models. Here’s an overview of the most popular ones used in the 3D printing community:

| Software | Type | Strengths | Weaknesses |

|---|---|---|---|

| TinkerCAD | Web-based | Beginner-friendly, drag-and-drop, cloud-based, fast prototyping | Limited geometry control, lacks advanced tools |

| SketchUp Free | Web/Desktop | Great for architectural/spatial work, easy extrusion, measurement tools | Not ideal for organic/precision work, STL export setup needed |

| FreeCAD | Desktop (Open-source) | Parametric, professional-grade mechanical design | Steep learning curve, outdated interface |

| Blender | Desktop (Open-source) | Advanced mesh/organic modeling, sculpting tools | Complex interface, not ideal for mechanical parts |

Geometry and Its Relevance in 3D Modelling

All 3D models are built from geometric primitives The 3D object primitives built into the software, which enable you to quickly generate many commonly used 3D shapes. —shapes like cubes, spheres, and cylinders—and then modified into more complex forms. Geometry is not just visual; it determines how your model behaves during slicing and printing.

A solid object in modeling software must be “watertight” A 3D object that is completely closed and has no holes, gaps, or overlaps in its surface geometry. . If your shape has gaps or disconnected faces, your slicer won’t generate a correct toolpath.

The complexity of geometry also affects print time and model stability The ability of a 3D model to maintain its intended shape and form. . Overly detailed meshes with thousands of faces may slow down processing and printing unnecessarily.

Flat surfaces and clean edges are ideal for accurate fitting parts.

Curved or sculpted surfaces require more careful modeling and slicing settings to preserve detail without overloading your printer.

Understanding how to construct geometry effectively leads to more reliable prints and makes post-processing easier.

Getting to Know the Software: TinkerCAD & SketchUp

SketchUp (Free Version)

SketchUp is commonly used in architecture, interior design, and spatial planning. It uses line-based modeling, where you draw in 2D and use the Push/Pull A technique used to create 3D shapes by extending or extruding a 2D shape or a face of an existing 3D object. tool to make things 3D.

Features include a clean drawing-based interface, push/pull extrusion, measurement and snapping tools Allow users to precisely align and position objects or their components to specific points, grids, or other geometry within the 3D scene. , and the ability to extend functionality with plugins for STL export. It is available as both web-based and desktop versions.

Use Case Example: designing a 3D-printed organizer that fits inside a specific drawer.

TinkerCAD

TinkerCAD is one of the most accessible and user-friendly 3D modeling tools available today, especially suited for beginners and those looking to quickly create printable designs. It is a browser-based application, meaning you don’t need to install any software—simply sign up and start designing directly in your web browser.

Summary of Key Terms

To conclude this chapter, here are the most essential takeaways:

- 3D models are built from geometry—faces, edges, and vertices forming solid, manifold shapes.

- Modeling software varies by purpose: TinkerCAD is ideal for beginners; SketchUp excels in architectural design; FreeCAD is strong for engineering.

- Terms like “extrude,” “boolean,” “mesh,” and “manifold” are not just definitions—they are tools you’ll use in nearly every project.

What Is 3D Scanning?

3D scanning is the process of capturing the shape and surface texture of a real object and converting it into a digital 3D model.

Scanning with a Smartphone

Thanks to modern cameras and AI processing, smartphones can be surprisingly effective 3D scanners. Many apps now use photogrammetry The science and art of extracting 3D information from photographs. or LiDAR A remote sensing method that uses laser light to measure distances and create highly detailed 3D models of objects and environments. (on supported devices) to capture depth information and reconstruct detailed 3D models. This makes it easier than ever for hobbyists and professionals to digitize real-world objects with just a few taps.

Popular Smartphone Apps:

- Luma AI (iOS) – Photorealistic NeRF-based scanning

- Polycam (iOS & Android) – LiDAR and photogrammetry options

- RealityScan (by Epic Games) – Easy workflow for Sketchfab

- Kiri Engine – Cloud-based photogrammetry for mobile and desktop

How to Scan with a Phone: Basic Steps

- Prepare the Object: Place in good lighting with minimal reflections.

- Capture from All Angles: Take photos or video while moving around the object.

- Upload or Process in App: Let the app reconstruct the model.

- Export the Model: Save as

.OBJ,.FBX, or.GLTF.

Tips for Better Scanning Results

- Use soft, diffuse lighting to avoid shadows and reflections.

- Keep the object still and move smoothly around it.

- Use visual markers for low-texture surfaces.

Post-Processing Your Scan

- Mesh Cleanup: Use software like MeshLab, Blender, or ZBrush.

- Retopology: Simplify and optimize the mesh.

- Texture Baking: Apply high-detail textures to a low-poly model.

- Export for Use: Use in games, AR, renders, or 3D printing.

Polycam 3D - Every Feature Explained (App Exploration)

| 3D Model | A digital representation of an object in three dimensions—width, height, and depth. | |

| .STL | The most common format for 3D printing, stores only the shape of the object. | |

| .OBJ | Similar to STL, but also supports color, textures, and material data. | |

| .3MF | Modern format for 3D printing, storing detailed information like color, materials, and print settings. | |

| Photogrammetry | The science and art of extracting 3D information from photographs. | |

| Snapping Tools | Allow users to precisely align and position objects or components to specific points, grids, or other geometry. | |

| Watertight | A 3D object that is completely closed, with no holes, gaps, or overlaps in its surface geometry. | |

| Mesh | A structure made of vertices, edges, and faces that defines the shape of a 3D object. | |

| Slicer | A program that prepares your 3D model for printing by converting it into layers and generating G-code instructions. | |

| Push/Pull | A modeling technique used to create 3D forms by extruding a 2D shape or a face of an object. | |

| Geometric Primitives | Basic 3D shapes such as cubes, spheres, and cylinders used as the foundation for complex models. | |

| Stability | The ability of a 3D model to maintain its shape and form during and after printing. | |

| Auto-Repair Features | Tools that automatically fix errors like holes, intersecting faces, and non-manifold geometry in a model. | |

| CAD (Computer-Aided Design) | Software used to create precise technical drawings and 3D models for printing and manufacturing. |